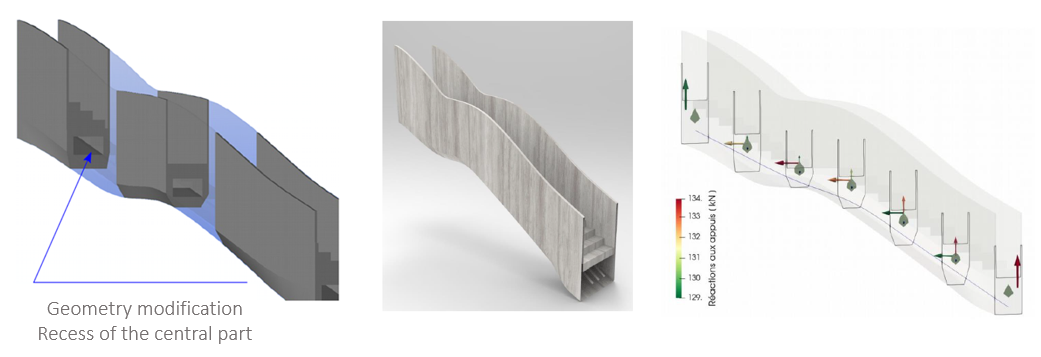

OUR IN-HOUSE RESEARCH LAB

Thanks to significant investments in R&D and the pursuit of new design and manufacturing trends, MINERAL EXPERTISE is a leader in the industry, constantly able to offer fresh impetus and design ideas to key market players. With a dedicated team of three engineers, our in-house research laboratory is central to our commitment to innovation. We focus on developing and utilizing advanced innovative technologies that challenge mineral standards and broaden the possibilities of its applications (Eco-Mineral-Glass® and Eco-Mineral-Process® are currently under patent review).